Vehicle Depollution – Complete Removal of All Operating Fluids

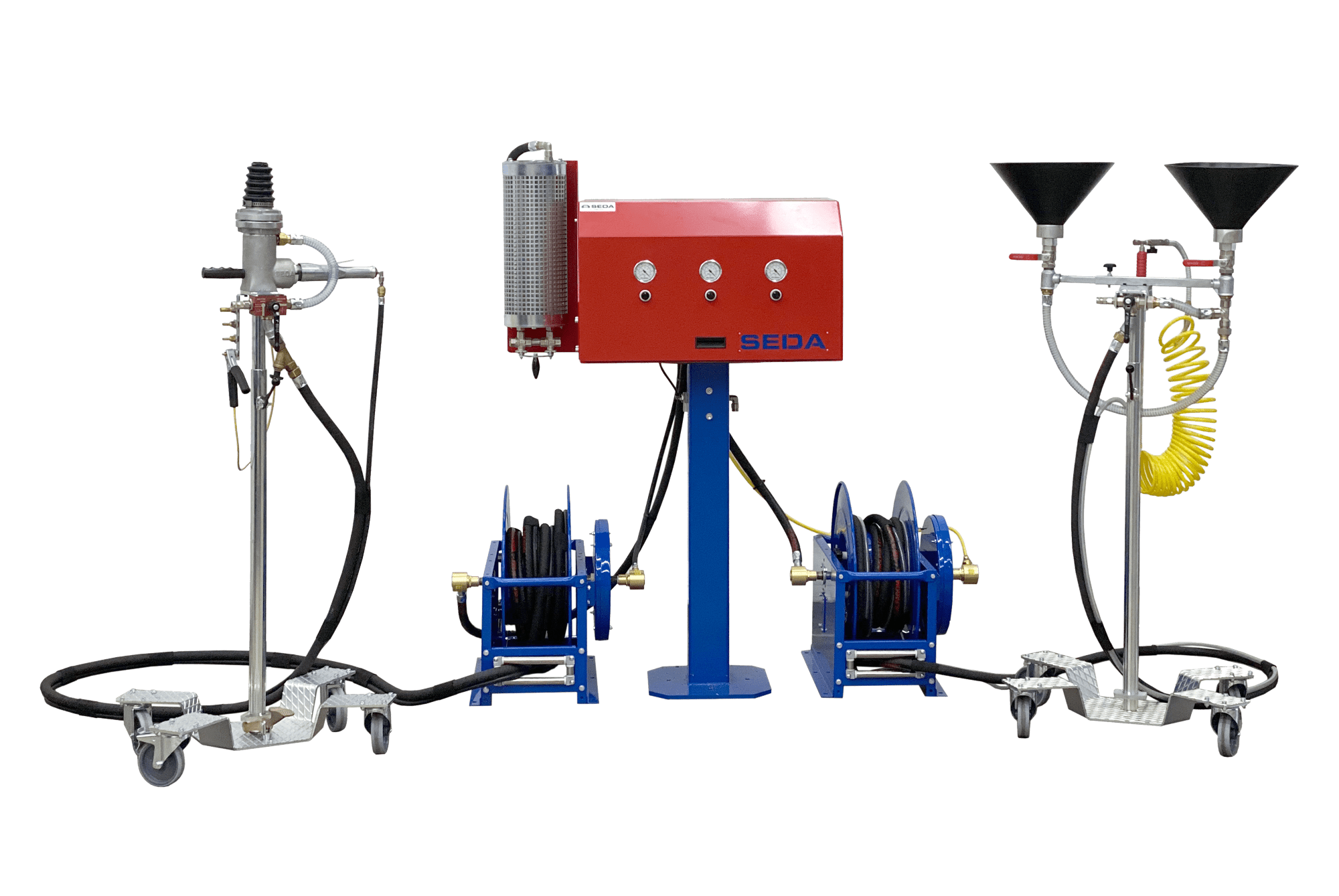

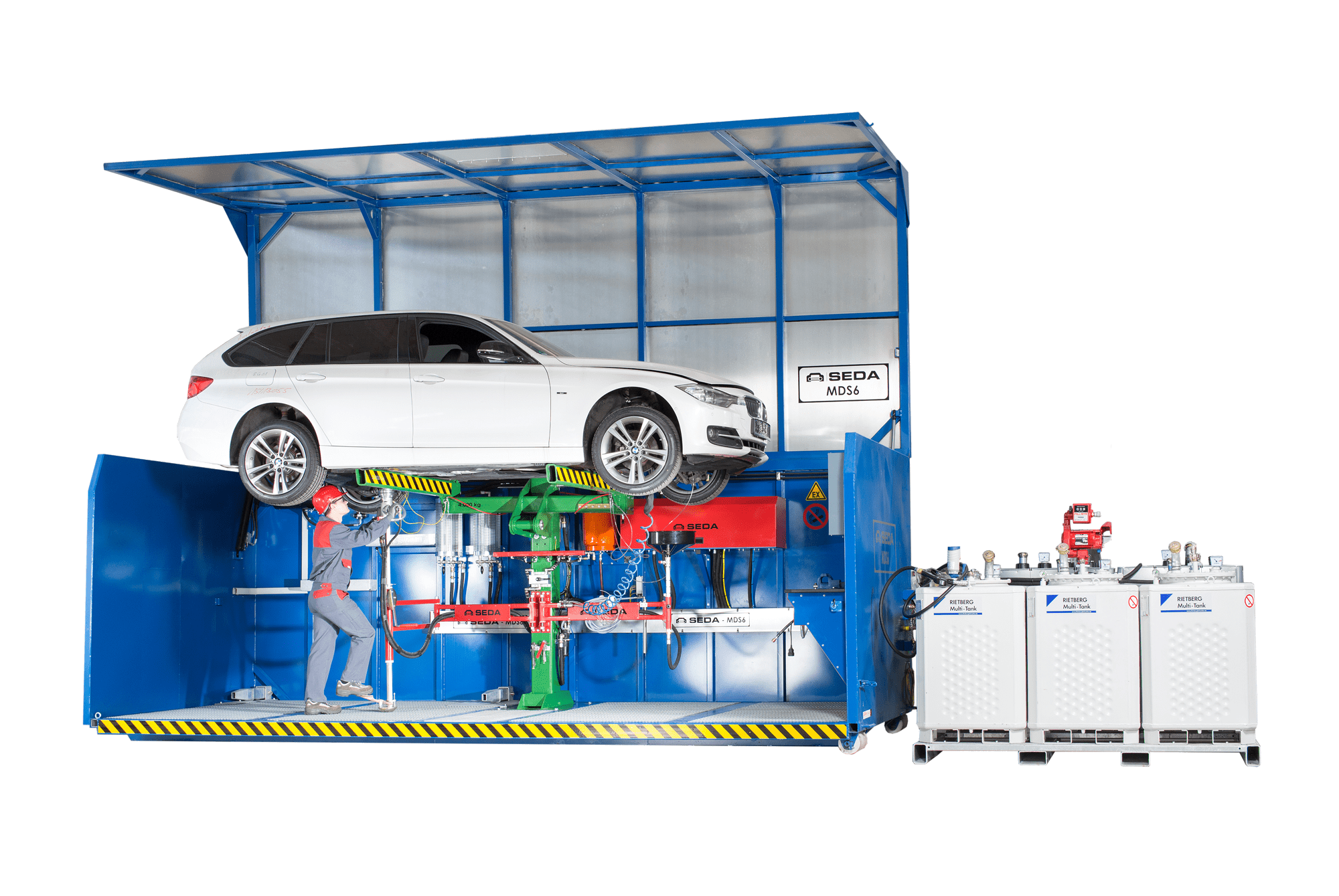

The depollution of end-of-life vehicles includes systems and devices for the complete removal of liquids such as petrol and diesel, waste oil, coolant, brake fluid, LPG, and urea (AdBlue). The systems are continuously developed and optimized to ensure maximum efficiency. SEDA supports you from planning through installation to ongoing service.

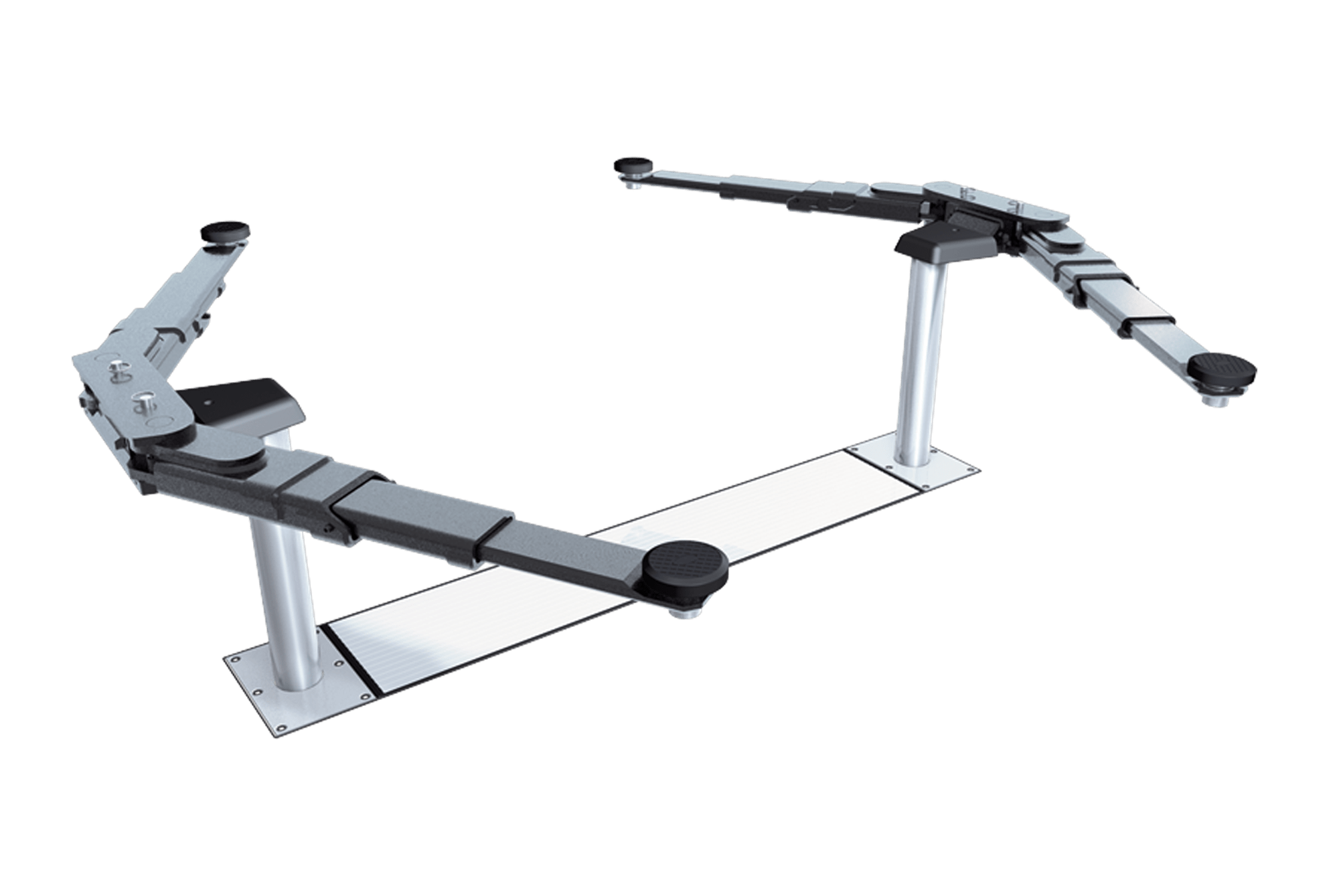

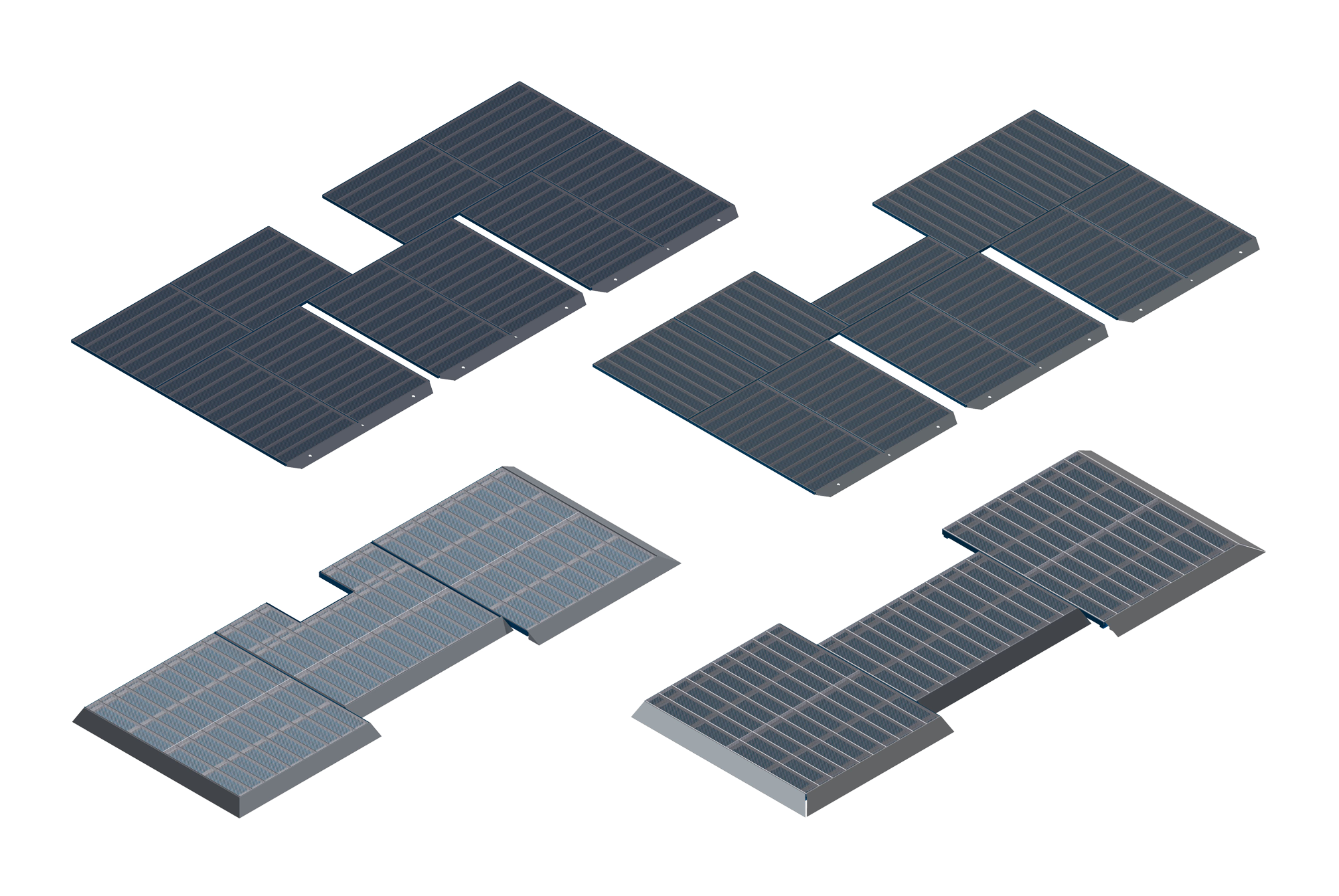

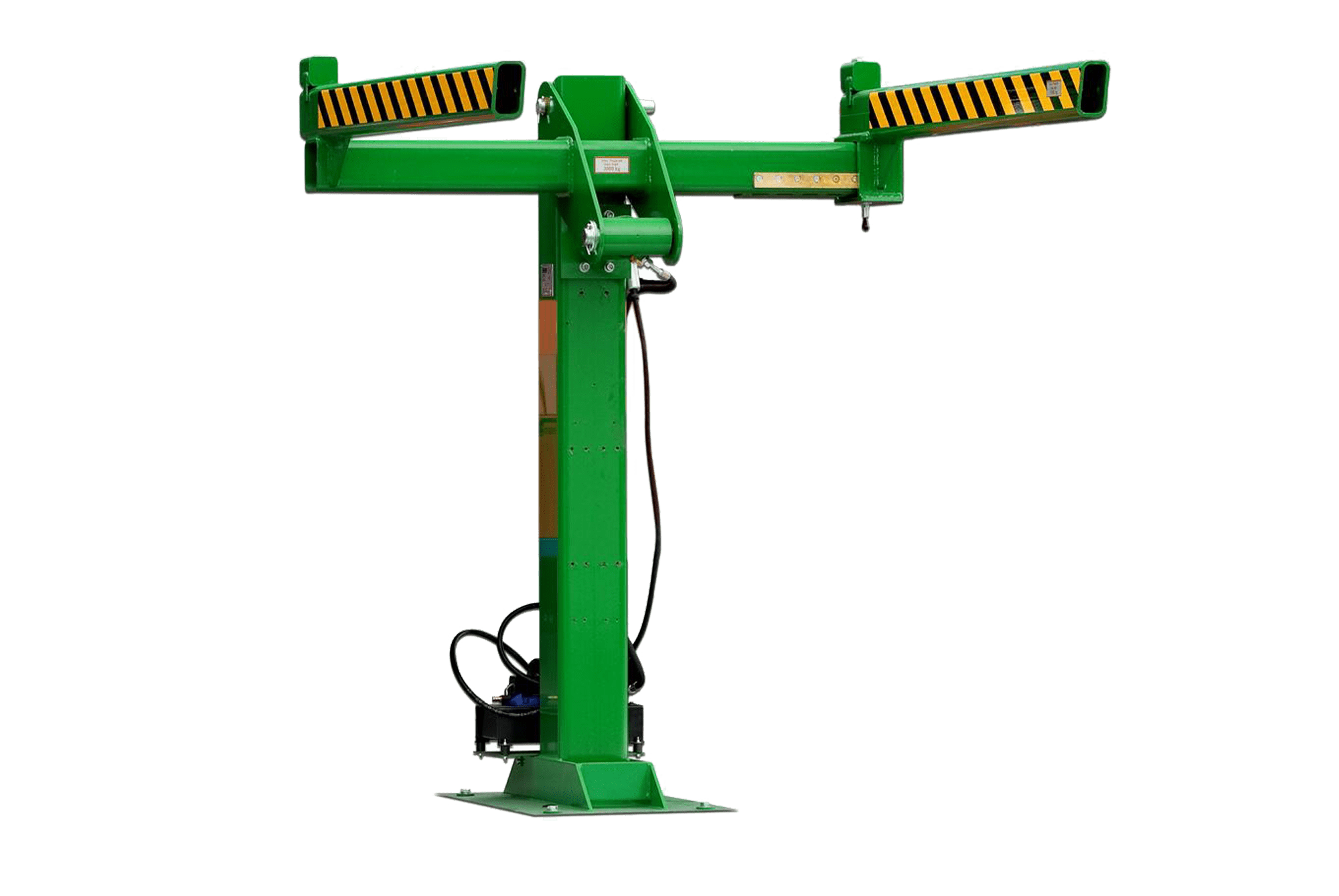

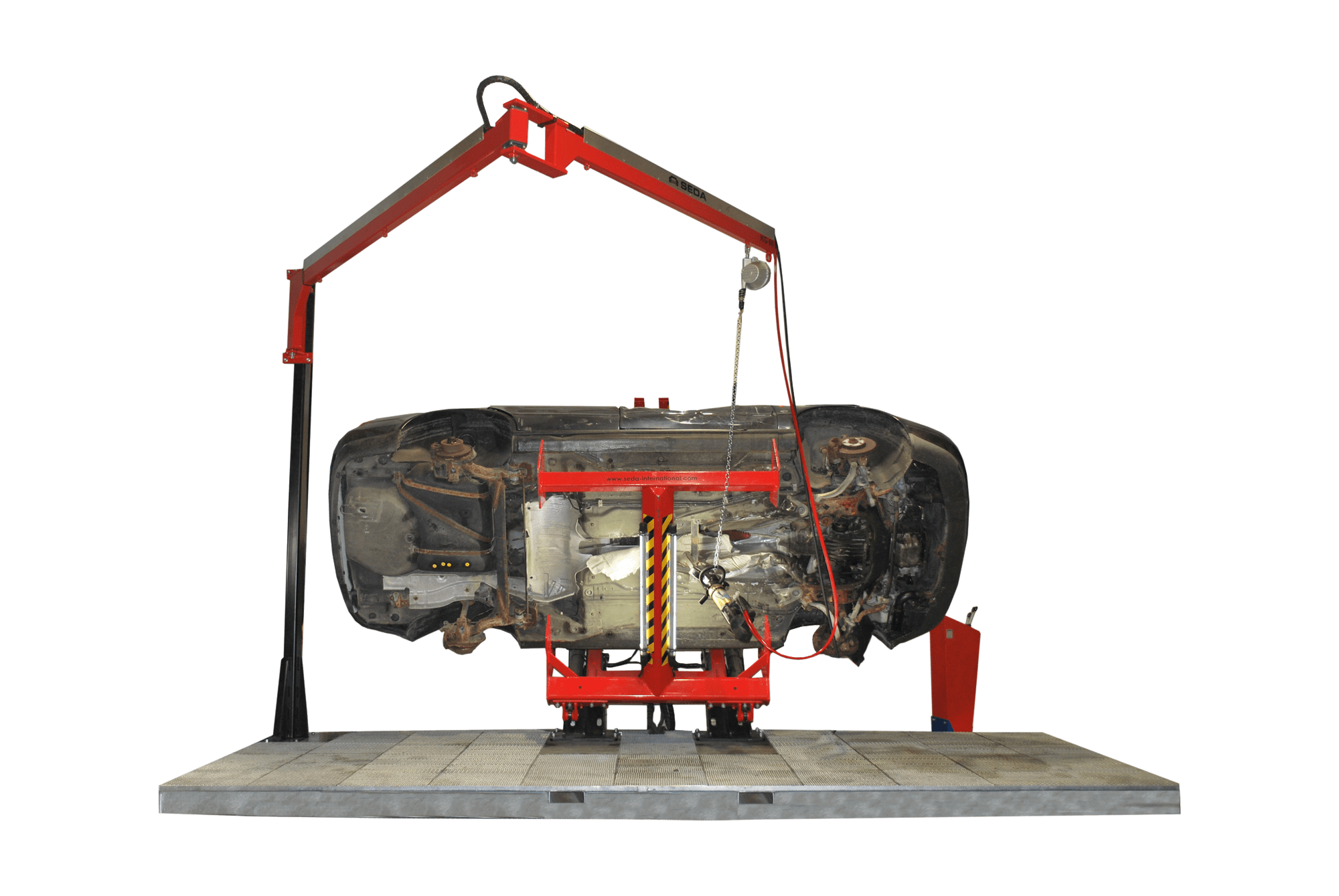

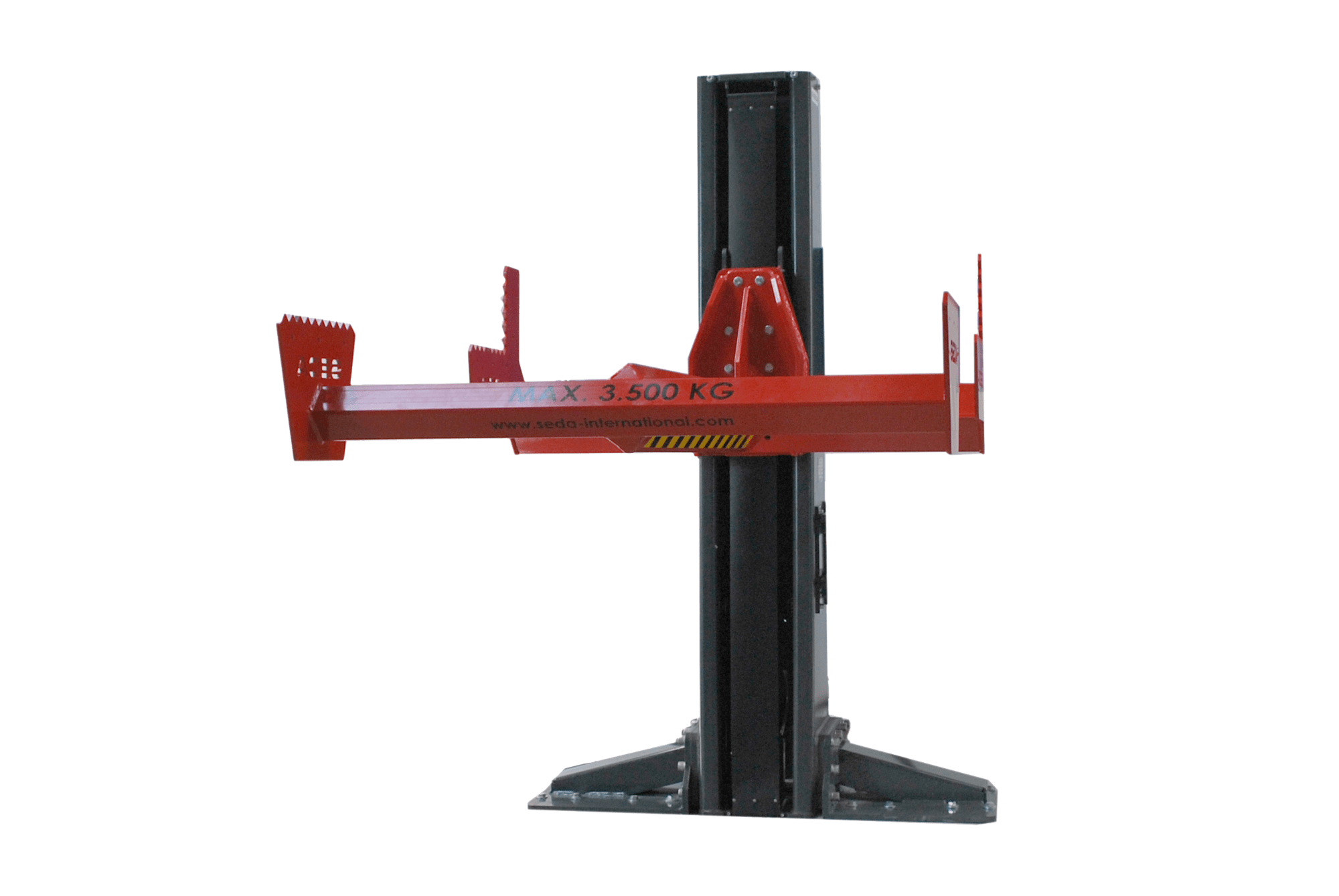

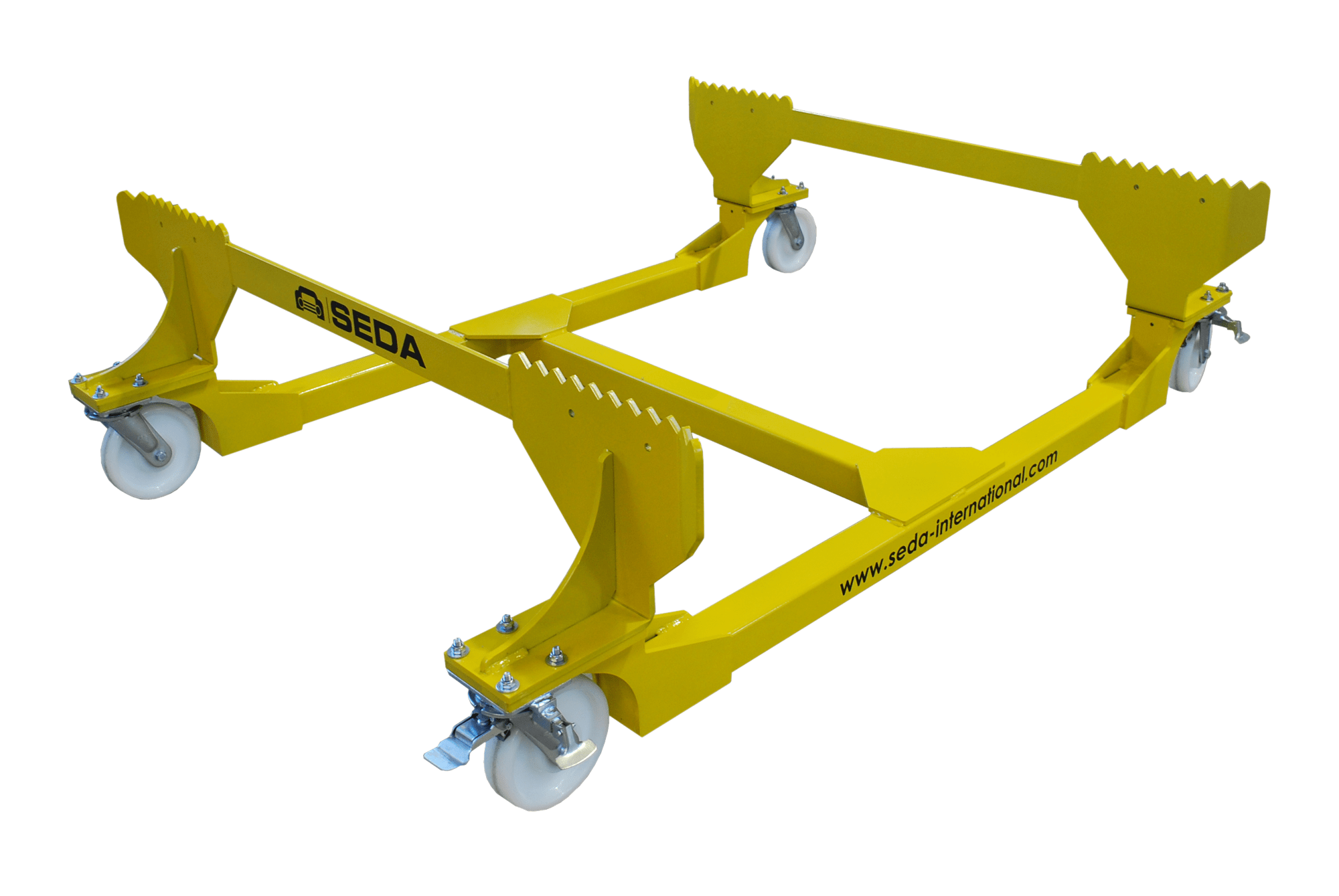

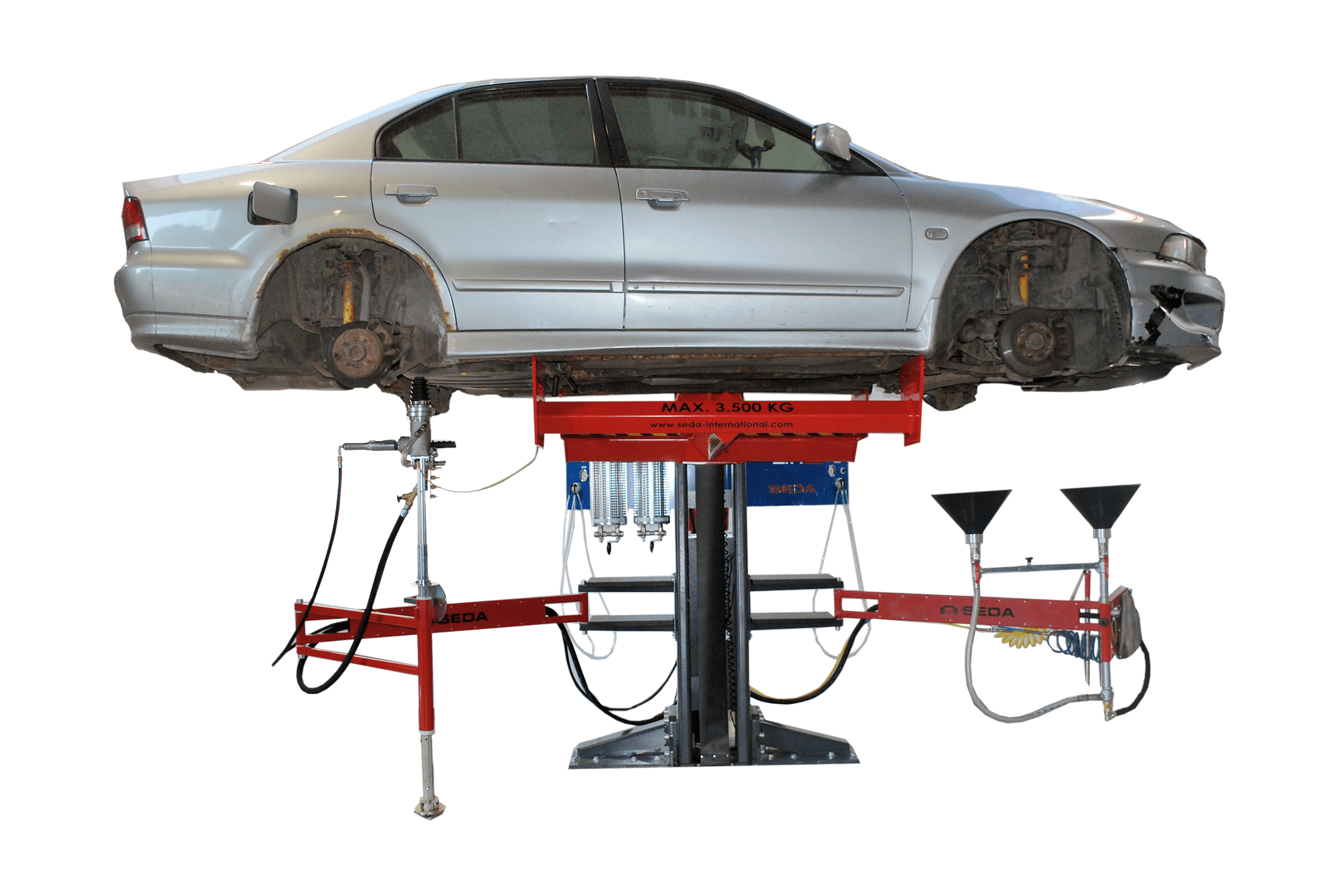

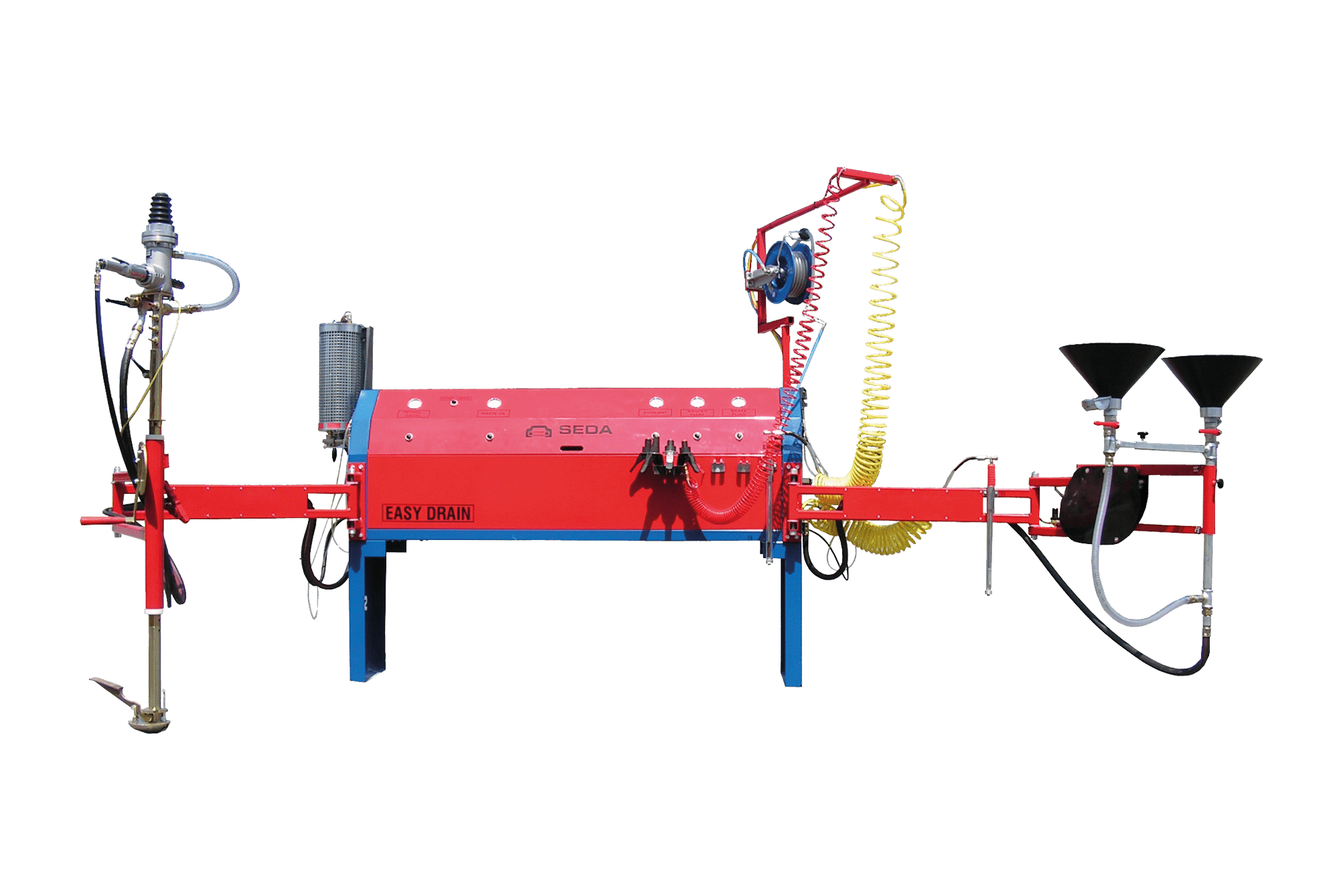

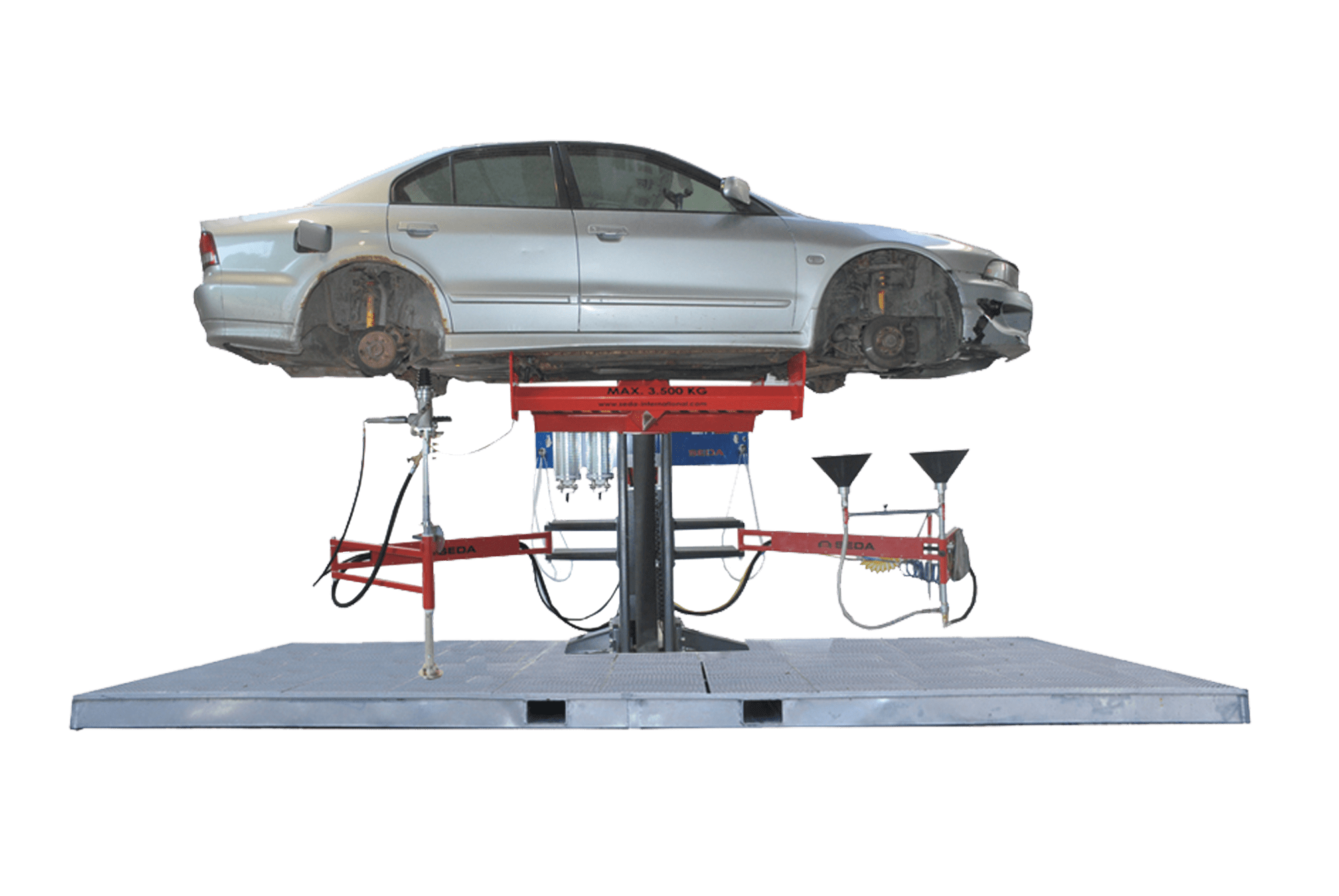

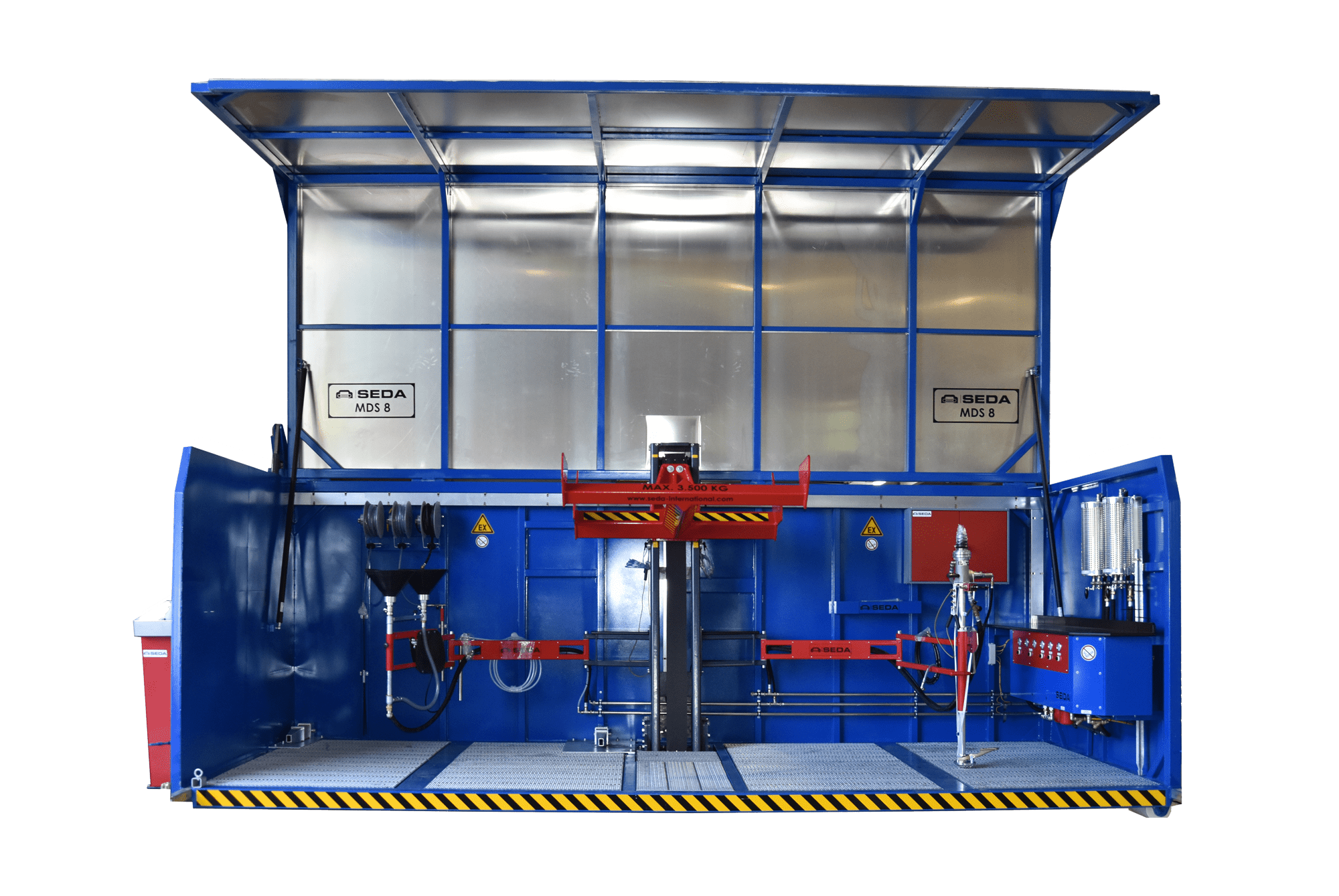

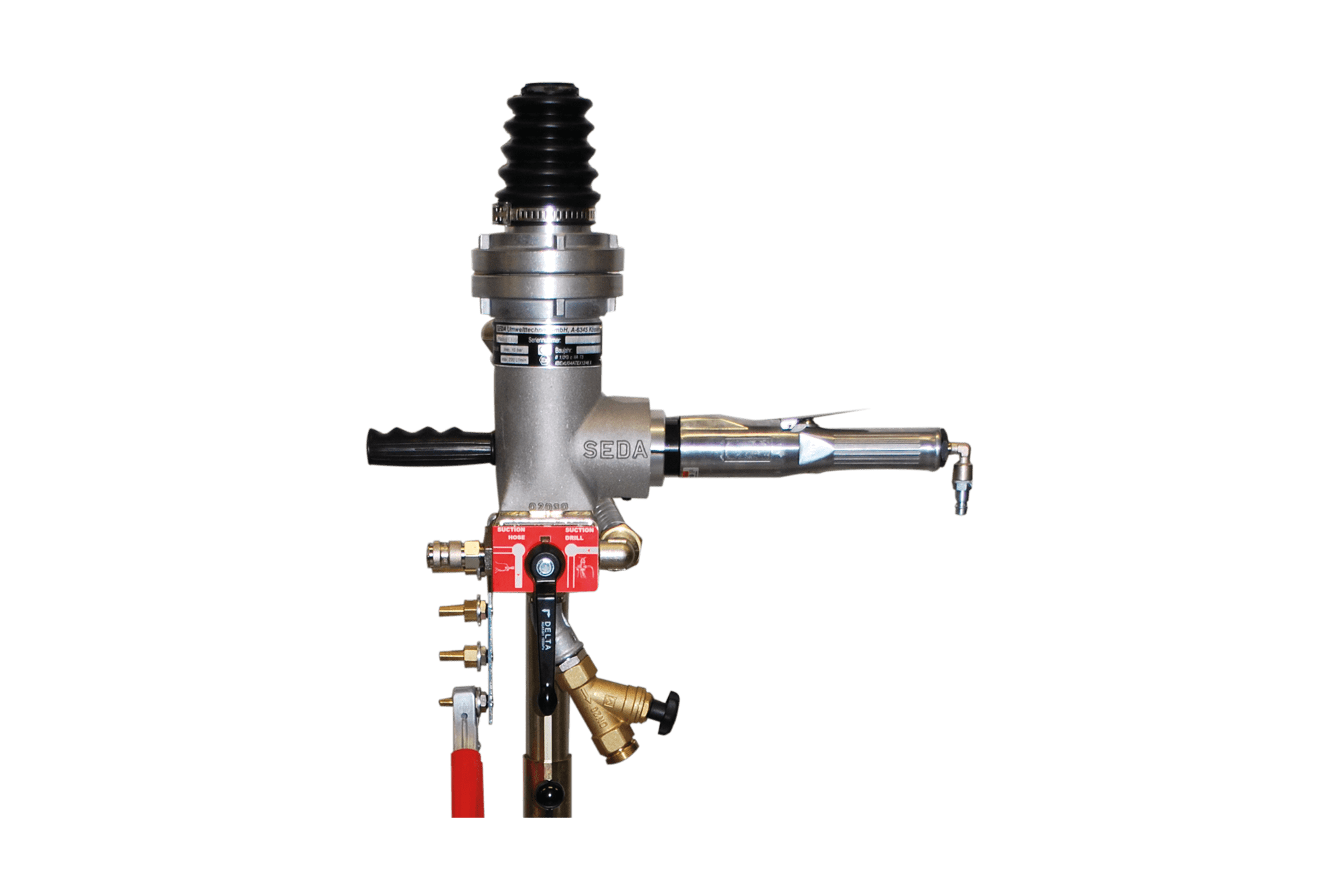

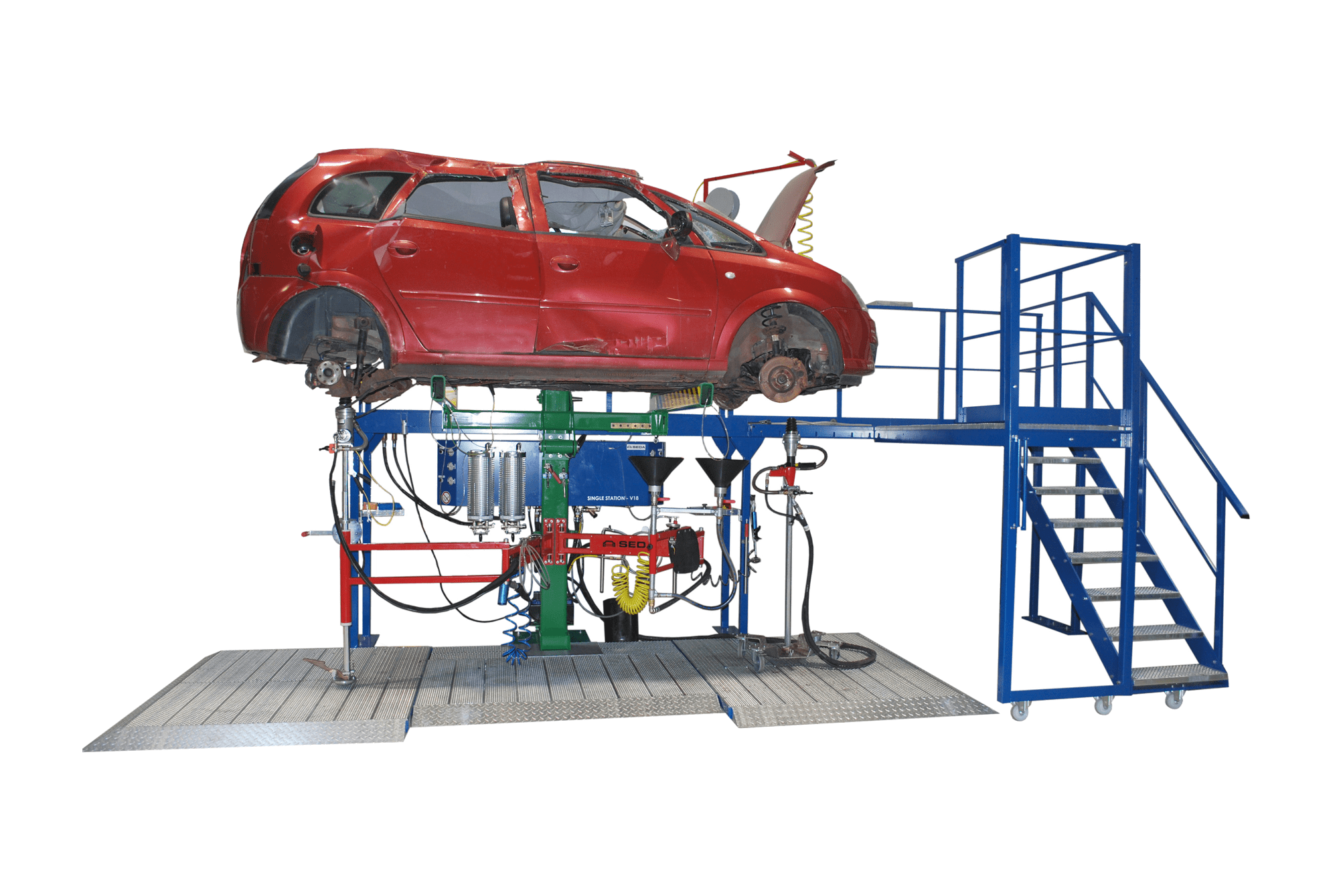

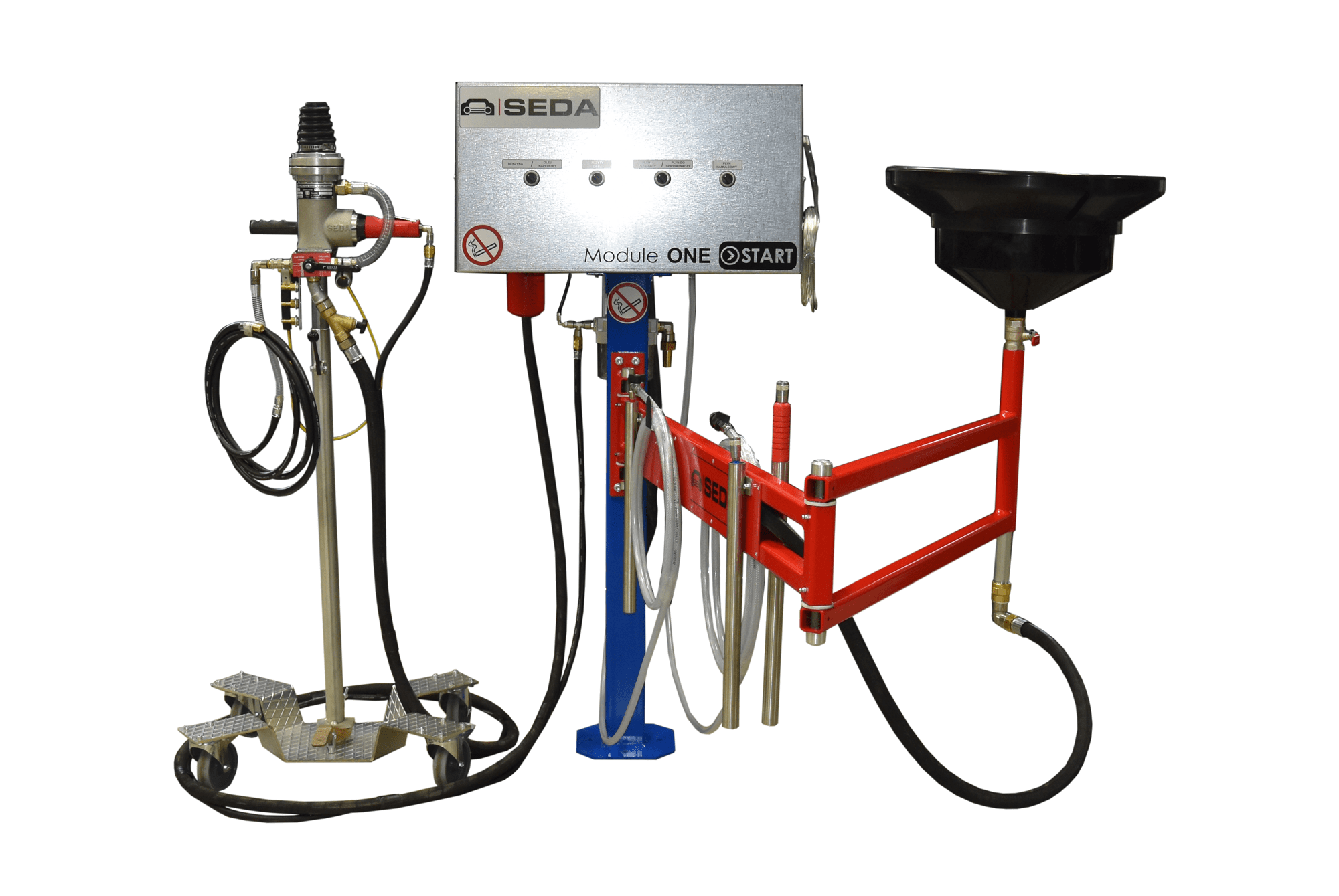

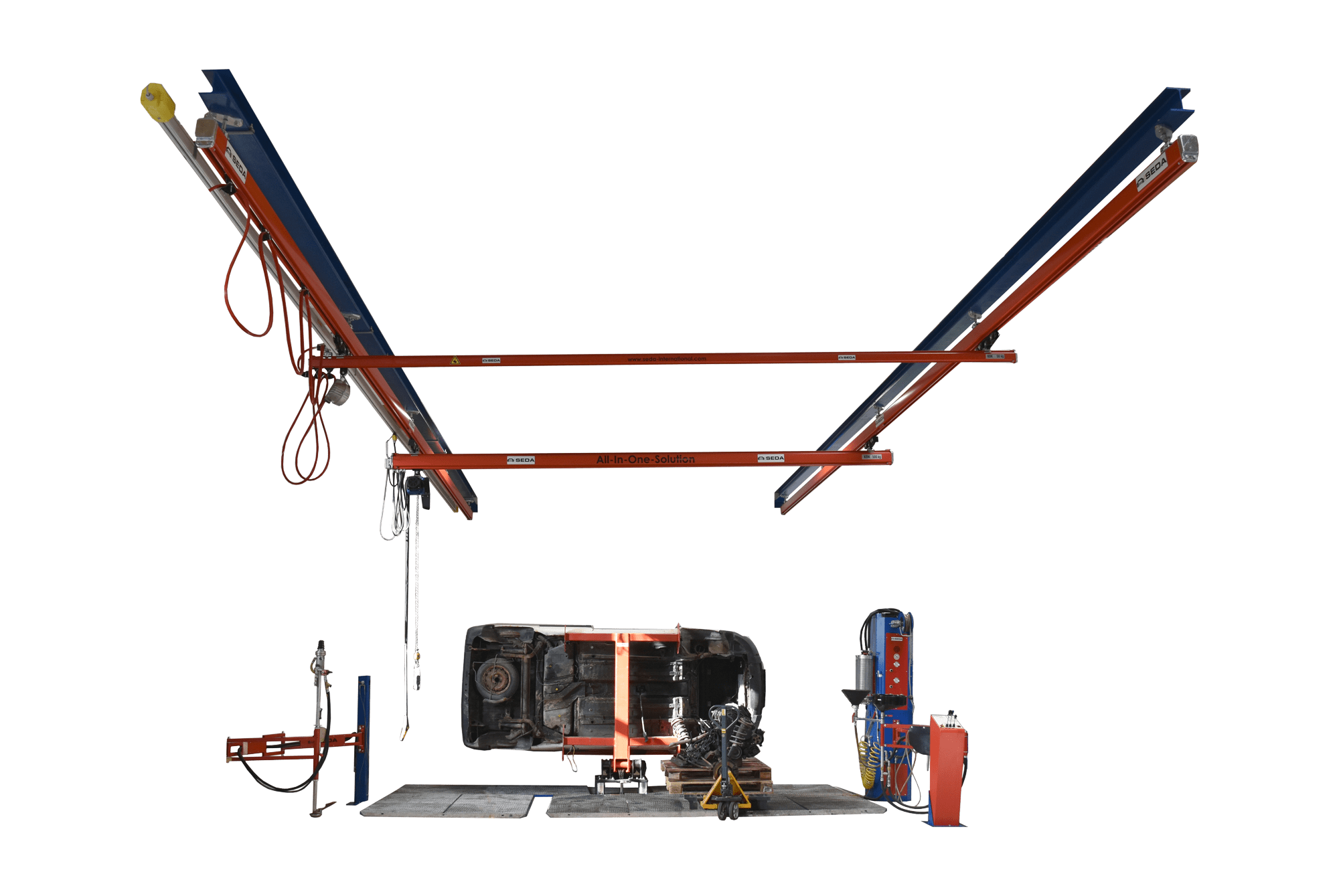

Stationary systems are permanently installed and custom-built to fit specific requirements. Mobile systems offer flexibility and can be relocated as needed to suit operational conditions, making them a practical alternative where stationary systems are not required. Devices can be used independently or integrated into complete systems. Each liquid has a corresponding extraction device to ensure safe and efficient removal. Vehicle racks enable secure access to the underside of the car for depollution purposes. Various platforms, lifts, and rigid vehicle racks provide optimal working conditions. Pre-installed systems are ready for immediate use, minimizing setup time and maximizing efficiency. Accessories include various components that simplify and enhance the depollution process, ensuring smooth and hassle-free operations.

Categories

Stationary

Devices

Vehicle racks

Accessories

How does the SEDA depollution process work?

Below, you will find an overview of the individual steps. You can also watch the complete process in our video, featuring a live demonstration from IFAT 2022 in Munich.

Planning & Installation

We are here to support you throughout the entire planning process, sharing our 40 years of industry experience to help you find the perfect solution.

- Consulting

- System Planning

- Local Laws & Regulations

- Showroom visit at SEDA

The ideal depollution system is chosen based on the number of vehicles processed per day, available space, and other key criteria.

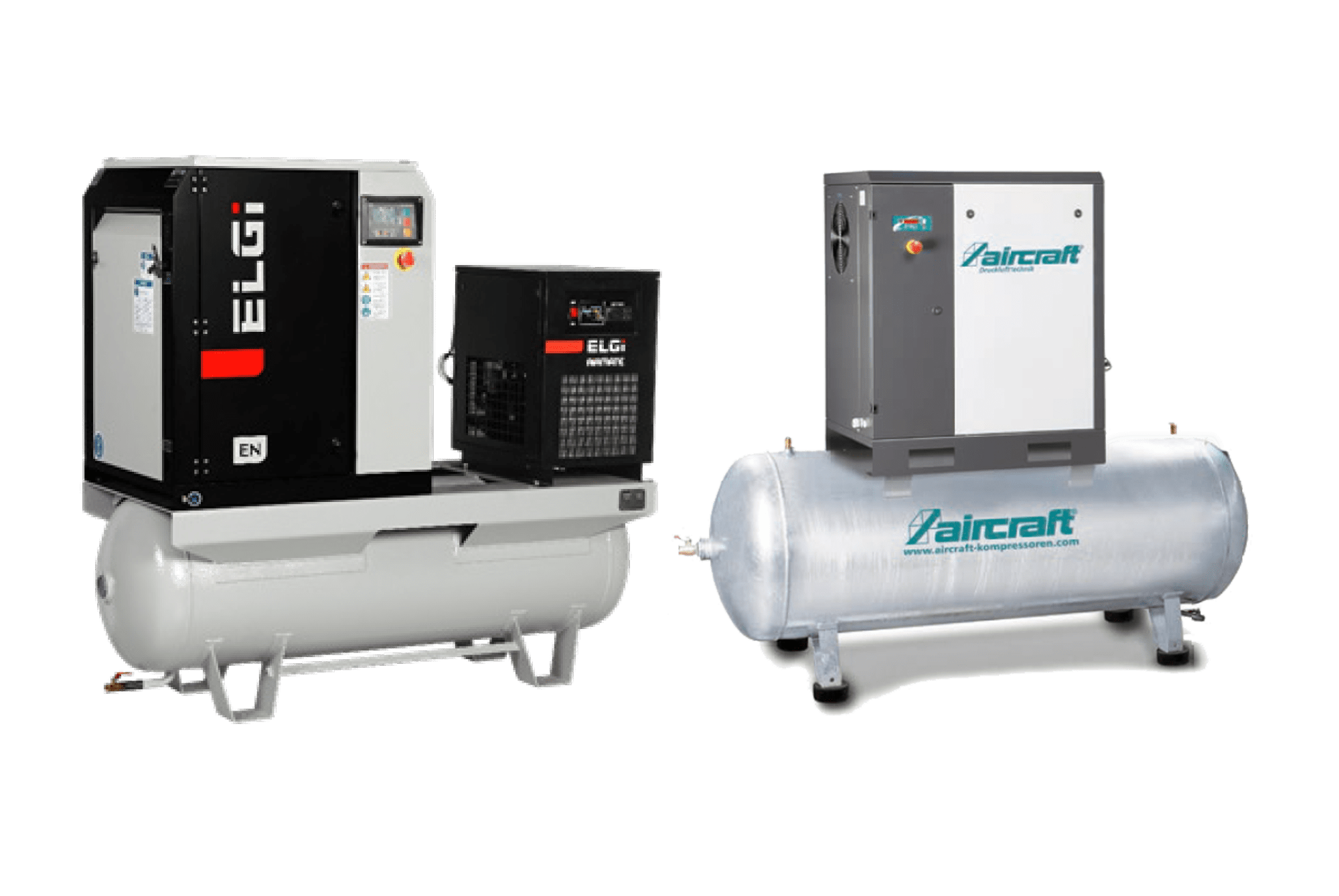

After selecting the vehicle rack, additional components such as storage tanks, compressed air supply, and the optimal flooring for the facility are determined.

The installation phase marks the completion of the process, including approval, certification, and comprehensive training for personnel.

- Installation

- Training

- Final Approval

Depollution & Service

Before depollution, the vehicle must be prepared by removing the battery, refrigerant, tires, and glass.

Using a SEDA system, all operating fluids are safely extracted. Specialized tools further enhance efficiency during the process.

- Fuel (Gas/Diesel)

- Waste Oil, Coolant

- Brake Fluid, Windshield Washer Fluid

- Urea (AdBlue), LPG, CNG, Hydrogen …

Following depollution, SEDA offers a range of tools for further vehicle processing, helping to recover valuable raw materials.

At SEDA, we place great importance on customer relations—before, during, and after project completion.

- Customer Service

- Maintenance

- Spare Parts

- Warranty

- Training