Individual devices for vehicle depollution of all types of liquids.

SEDA individual devices can be used either as part of systems or independently. For each type of liquid or substance, there is the corresponding device, ensuring efficient suction without wasting a single drop.

Categories

Stationary

Mobile

Devices

Vehicle racks

Accessories

Overview of depollution devices

As the global market leader in the manufacture of systems for vehicle depollution, we offer a highly diverse range of individual devices for the reliable removal of used oil, gas, diesel, LPG, and many other substances, the removal of which is essential for environmentally friendly vehicle recycling. Efficiency, ease of handling, cutting-edge technology, and safety are at the core of all our products.

Automated processes and easy handling

With SEDA, you not only benefit from an extensive product selection but also from fully automated technology, where we place great value on the protection of people and the environment.

We will gladly tailor the depollution devices to suit your specific operational needs. Additionally, we expand your stationary or mobile vehicle recycling platform with products whose handling and dimensions perfectly match your requirements.

Below are some application examples.

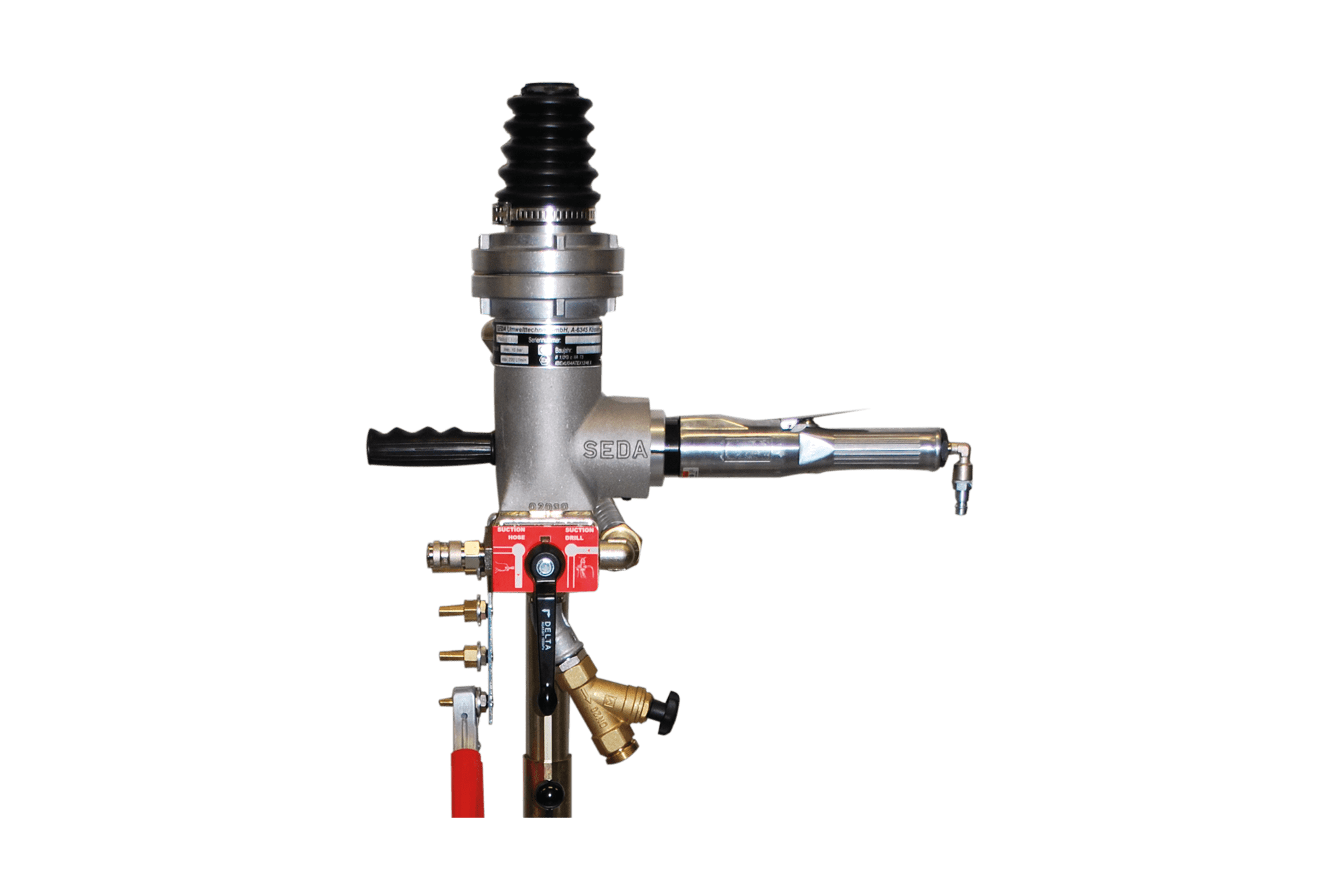

Products for drilling/emptying tanks

Specifically for smaller businesses, we developed the GreenPoint TankDrillingDevice. In about 5 to 10 seconds, the drill cleanly penetrates the tank, after which the fuel is immediately suctioned out and then passes through multiple filters. Thanks to its robust, compact design and easy handling, the SEDA GreenPoint TankDrillingDevice is one of the most widely used depollution individual devices worldwide.

Products for suctioning shock absorber oil

The SEDA SOG2 is specifically designed for the unique requirements of removing shock absorber oil. With this device, you can quickly, cleanly, and safely suction the oil from mounted shock absorbers, ensuring complete extraction with minimal effort.

Products for gas removal

SEDA offers professional suction devices for emptying LPG and CNG tanks. Our LPG Recovery ECO, for example, was specifically developed for LPG car tanks. You can directly channel the liquefied petroleum gas extracted from vehicles into the integrated storage tank. This is a compact system designed for gas extraction and combustion. All processes run automatically, ensuring efficient end-of-life vehicle emptying.