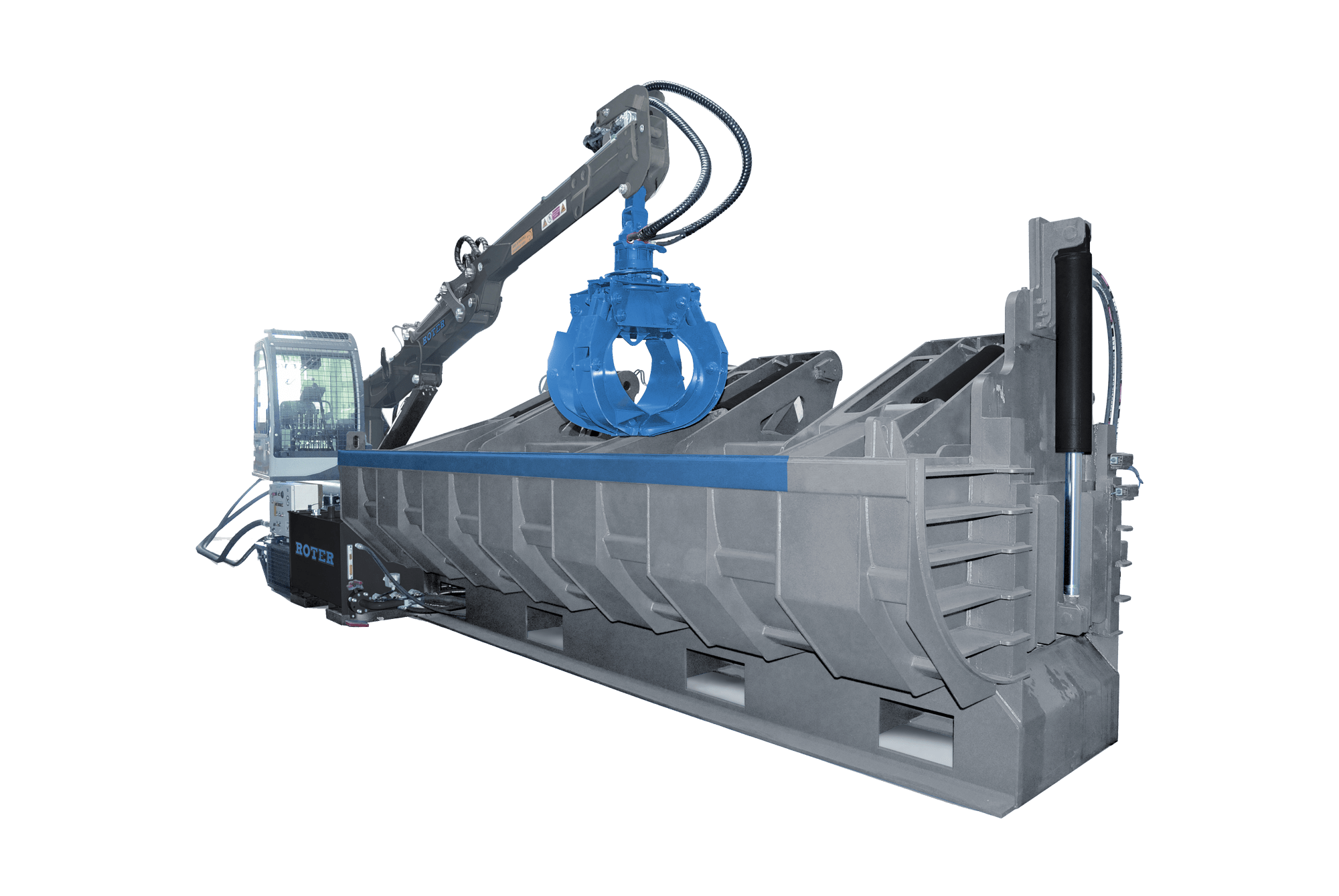

SEDA Car Baler

The SEDA car baler is specifically designed for compressing vehicle bodies and is the ideal choice for auto recyclers who need compact scrap bundles for space saving storage and efficient transport.

This powerful press is available in stationary, semi-mobile, or mobile versions, as well as a 3-axle trailer configuration, which can be customized to meet the recycler‘s specific requirements. With three high-performance hydraulic cylinders per lid, it offers the highest pre-compression force on the market and is characterized by its particularly robust construction.

Technical Data

| Box material | HARDOX 400/450 |

| Box length | 19.68 ft |

| Box width (open) | 5.74 ft |

| Cylinders per lid | 3 |

| Lid compression force | 200 t |

| Main cylinder compression force | 155 t |

| Bale size | ca. 2.88 x 2.13 ft |

| Oil circuit capacity | 185 USG |

| Diesel tank capacity | 24 USG |

| Motor power | 145 kW / 106 PS |

| Operating pressure | 4061 PSI |

| Capacity for scrap metal | 8-14 tonne/hour |

| Capacity for scrap | 15-20 tonne/hour |

| Weight (Standard conf.) | 22 tonne |

Order Number

| Y-37200 | SEDA Car Press (RR6/D) as a stationary 6-meter version with a diesel engine and an ejection flap |

| Options | |

| Sizes | 16.4 feet (RR5), 19.7 feet (RR6) both stationary, with diesel engine and remote control |

| Alternative engine | Electric engine 1 x 90 kW oder 1 x 70 kW (EM) |

| Alternative design | Hydraulic lifting legs (LL), Roll-off container (RORO), 3-axle trailer (MOB) |

| Special equipment | Ejection flap (D), crane with cabin (CR), rotating grab arm (G300), hydraulic oil heating (OH), engine heating (CH), fluid collection container |

Downloads

Benefits

- Highest pre-compression force on the market

- Largest loading box worldwide

- Extremely robust construction with long service life

- No foundation required

- Low maintenance with easily accessible components

- Suitable for a wide range of metals and steel

Video

Additional information

The baler is suitable for the efficient compression of various types of metal, including steel as well as ferrous and non-ferrous metals. The car press is designed for demanding applications and can be flexibly adapted to specific production needs. In addition to the standard diesel drive, an electric motor is available as an option. The system can also be equipped with a crane with a driver’s cabin and a special ejection flap.