SEDA DrainTower

The SEDA DrainTower is available as a double or single system and is characterized by its compact design and high efficiency.

Depending on the configuration of the system, the ATEX-certified tank tapping device, in combination with powerful vacuum pumps, enables the safe extraction of petrol/diesel, waste oil, coolant, brake fluid and windshield washer fluid from end-of-life vehicles.

compliant with ATEX

vacuum gauges for each fluid

and outlets located at the top

extracted by

combining pumps

large door

Technical Data

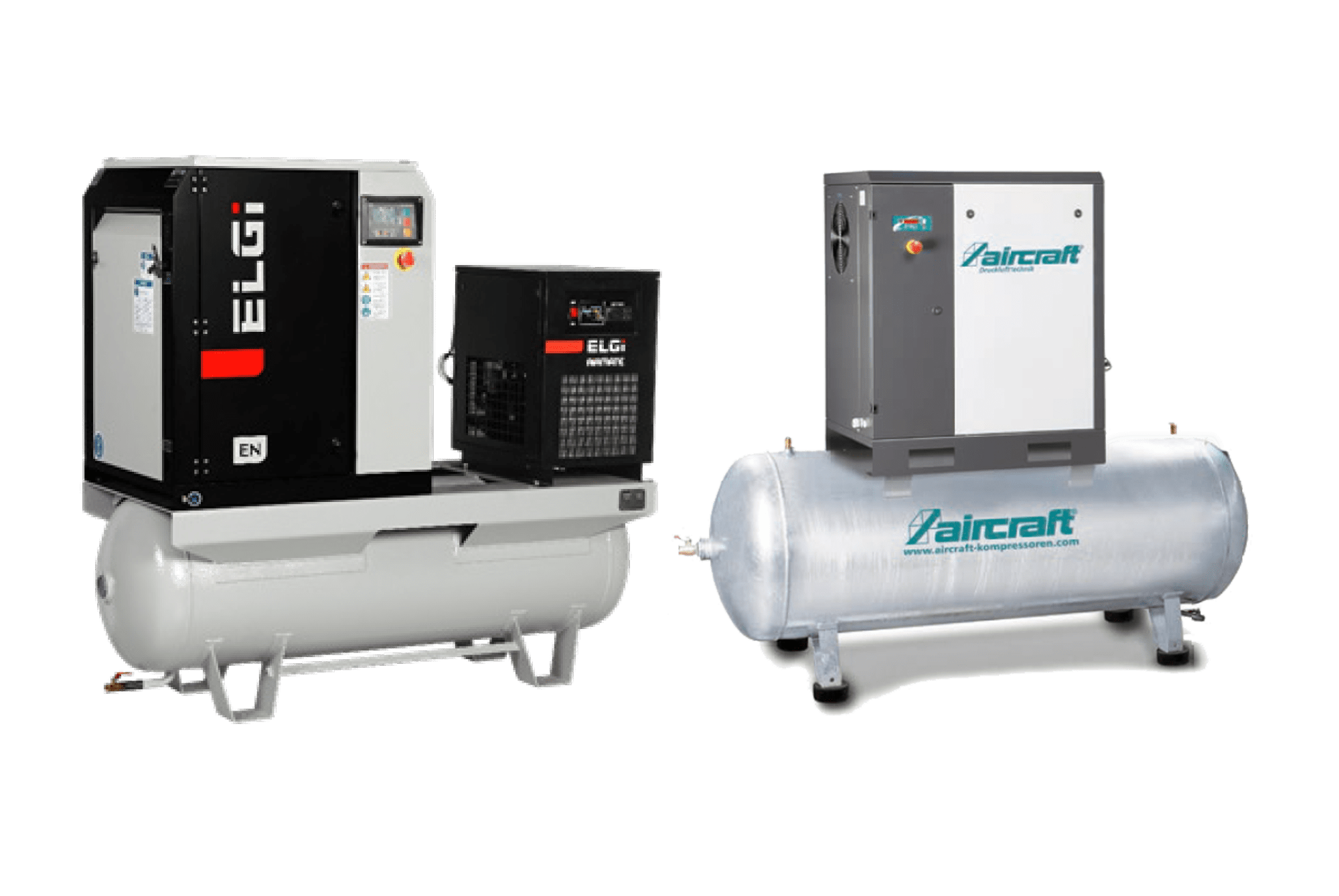

| Compressed air | 8.5 bar -1,210 l/min |

| Liquids | Gasoline / diesel Used oil Brake fluid Coolant Windshield washer fluid |

| Space requirement single/double | 6.9 x 3.5 m / 7 x 4 m |

| Weight single/double | 330 kg / 600 kg |

Order Number

| A-51048 | SEDA DrainTower single |

| A-51049 | SEDA DrainTower double |

Downloads

Benefits

- Complete drainage

- Pneumatic control panel

- Pre-installed technology

- Powerful pumps

- Explosion protection with ATEX tank drilling device

Video

Additional Information

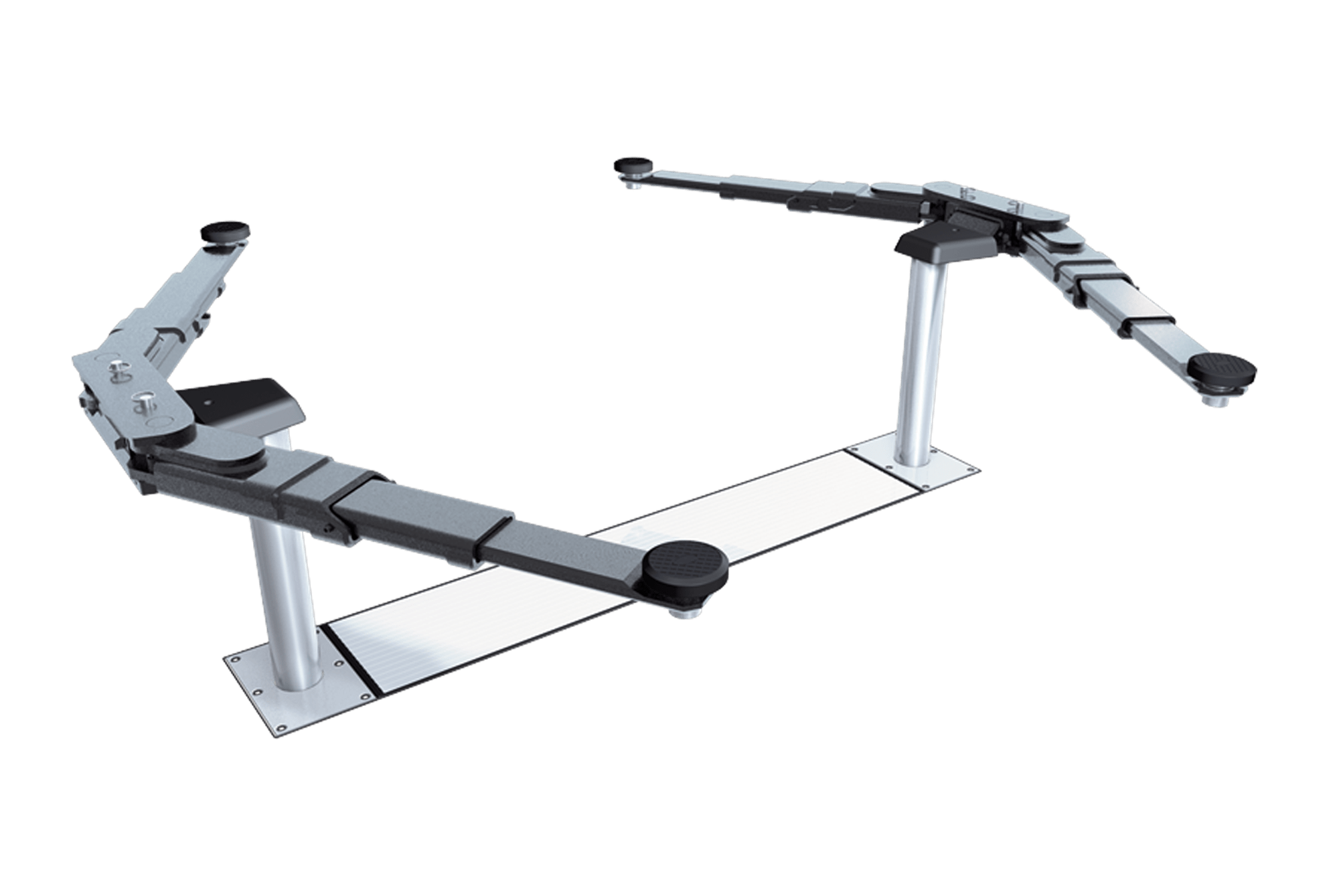

The SEDA Drain Tower comprises a fully hosed tower containing pumps, filters and a maintenance unit. The system has a modular design so that different components can be used depending on the configuration. Separate pumps for petrol and diesel are available for fuel extraction, or alternatively a combined pump for both fuels, each with an integrated filter and pneumatic control. A tank tapping device, in regular or heavy-duty design, is mounted on a mobile chassis.

Depending on the configuration, the system offers a waste oil pump, a swivel arm with single or double funnel, a gearbox tapping device and a suction gun for hydraulic oil for extracting waste oil. In the brake fluid area, either a vacuum container or a special brake fluid pump are integrated as required, supplemented by suitable hoses, brake line pliers and pressurization.