Shredders for Cable and Plastic Recycling

SEDA products stand out through all developments with reliable quality, ease of use, and great functionality. Thanks to our many years of experience, we understand the needs of recycling companies and automobile dismantlers, offering machines tailored to these requirements.

These quality standards are, of course, also met by our cable shredders and plastic shredders.

Categories

Car Press

Refrigerator Rec.

Cleaning Tools

Cutting Devices

Shredder

Cable Shredders – Plastic Granulation with Metal Separation

Cable waste contains valuable metals that can be reintroduced into the material cycle through modern recycling processes. Copper is particularly sought after, but aluminum, steel, or lead can also be recovered from cable waste and used in industrial processing. However, a clean separation of plastics and an even granulation of the metals is a prerequisite for this.

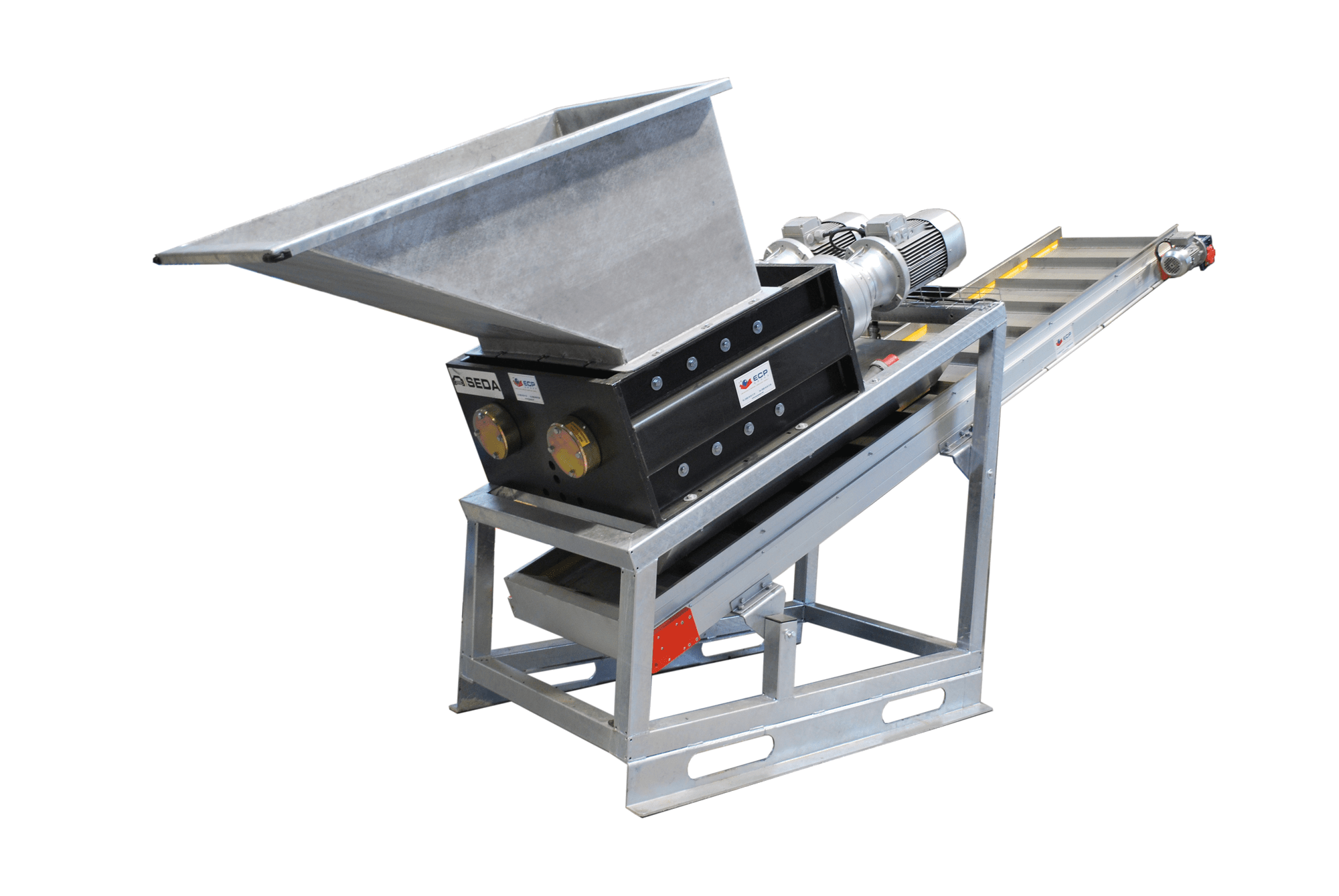

The cable shredders impress with integrated metal separation through easy operation and maximum functionality. They separate the plastic from the metal and then ensure the separation of the metal and its granulation. Specifically for auto recyclers, we have developed a complete system that includes a pre-shredder with conveyor belt, magnetic separator, and powder dosing unit. The machine enables a complete, fast, and smooth recycling process for car cables.

Top-Quality Plastic Recycling

With the plastic shredder, you get a versatile granulator with powerful cutting tools. It effortlessly shreds plastics such as plastic drums up to a volume of 200 liters, pre-shredded pipes, bumpers, punching grids, or rubber granules. These materials are fed into the granulation process through an opening measuring 62 x 84 cm. The resulting small plastic parts are emptied into a container via a conveyor belt.

The operation of the plastic shredder is very user-friendly. Two compression areas ensure that the bearings and gearbox inside the machine are protected. In addition to manual loading, an option for loading via a conveyor belt, elevator, or screw is also available.