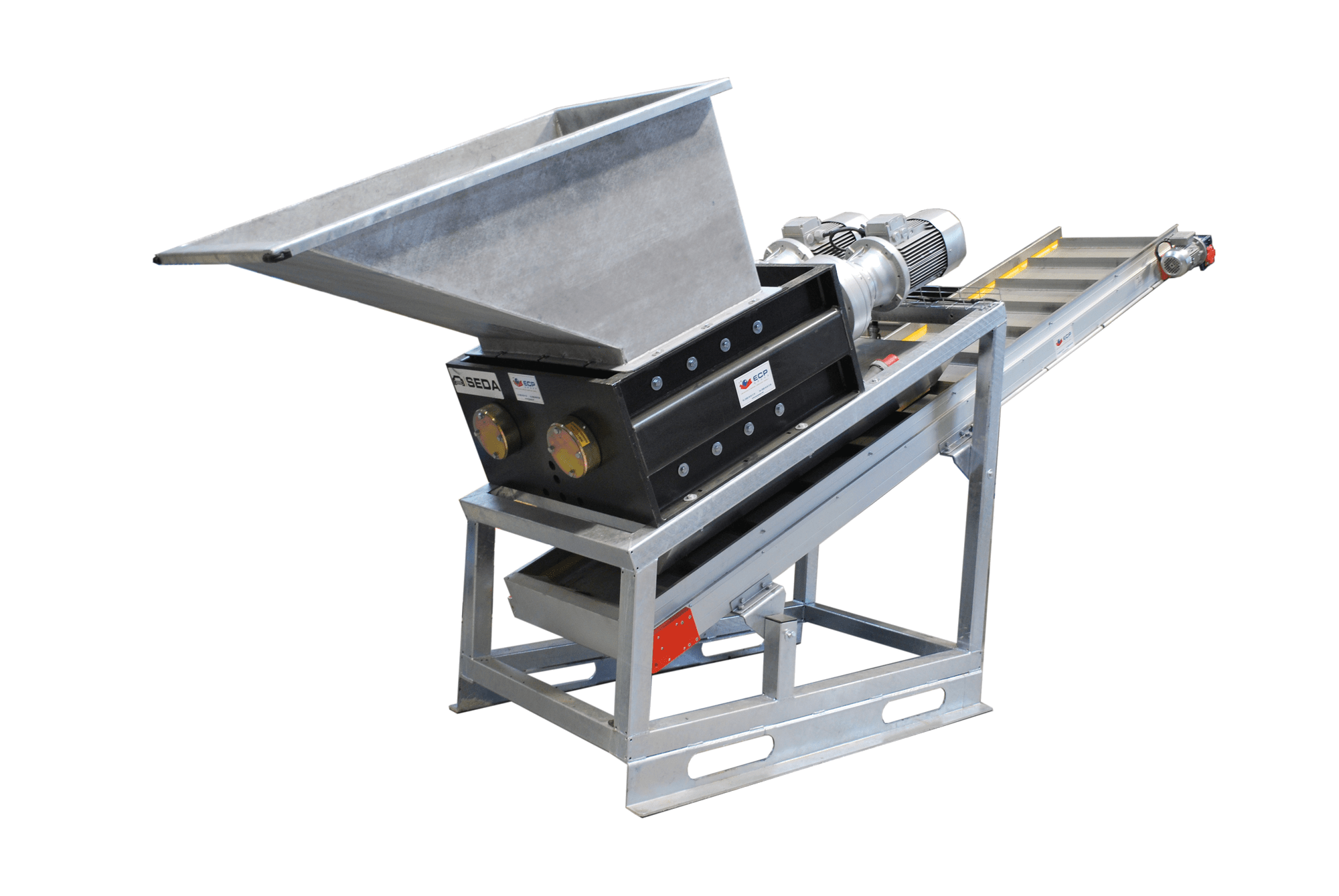

SEDA Car Flattener

To minimize the costs of transporting car wrecks to the shredder, it is essential to compress vehicle bodies so they are flat enough for space-saving storage and efficient transport.

The car flattener features two robust folding lids on the sides of the press, which exert a pressing force of 110 tons. This compresses car wrecks in a single operation to a length of 3.8 meters and a height of approximately 35 cm (depending on the model). Any liquids that escape during compression can be collected and directed into an external container. The car flattener is available in both stationary and mobile versions, ensuring cost-effective transport through flattened vehicle bodies.

Technical Data

| Dimensions | 9,4 x 2,8 x 3,73 m |

| Weight | 22 t |

| Pressing force of the two folding lid cylinders | 2 x 940 kN / 330 bar |

| Drive power | 30 kW |

| Open dimensions | 5,7 x 2,2 m |

| Closed dimensions | 4,3 x 2,2 m |

| Height of compressed vehicle | ca. 350-400 mm |

| Ground clearance | 1,21 m |

| Oil circuit capacity | appr. 500 l |

| Cycle Time/Pressing | appr. 50 sek |

Order Number

| N-37100 | SEDA Car flattener manual electric |

| N-37101 | SEDA Car flattener manual Diesel |

| N-37102 | SEDA Car flattener automatic elektric |

| N-37103 | SEDA Car flattener automatic Diesel |

Downloads

Benefits

- Fully automatic operation

- Optimal transport efficiency through compression

- Liquids are collected and drained safely

- Durable folding lids

- Available in stationary or mobile versions

- Long service life thanks to robust construction

Video

Additional information

The SEDA car flattener can handle medium-sized vehicle bodies (including the engine) with a loading capacity of 13 to 15 tons. This ensures a freightspace utilization of 90 to 100 percent, especially for trucks with a payload capacity of 15 tons, optimizing the use of transport capacity. The AutoFlattener is available with either electric or diesel drive and can be operated manually or fully automatically via remote control. Optional features include noise protection, an oil drip tray beneath the press with a submersible pump for liquids and a centralized grease supply system for the maintenance of lid and cylinder bearings.