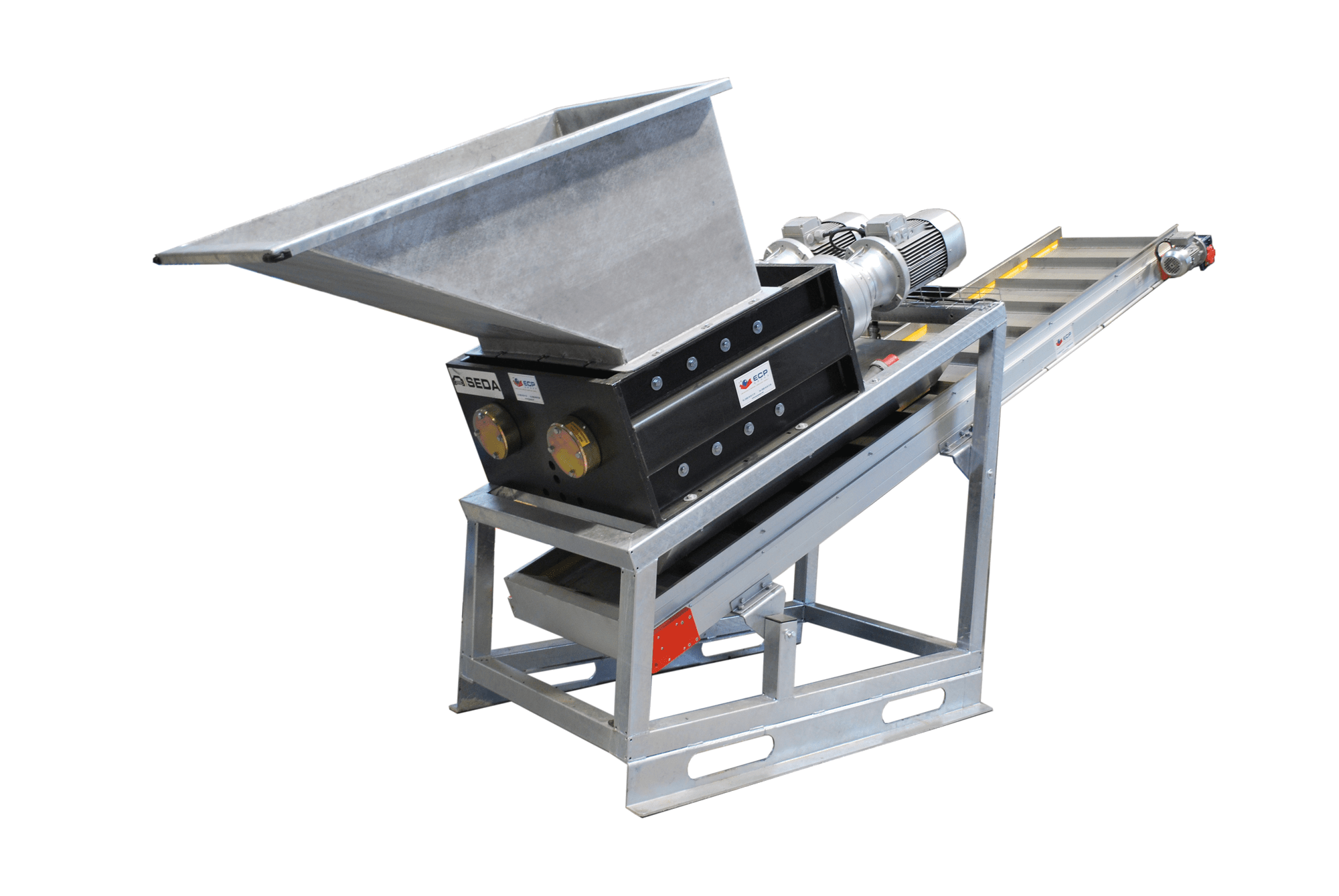

SEDA AFR Container

The SEDA AFR Container offers an optimal solution for the initial stage of refrigerator recycling.

The system integrated into a 20 footcontainer is designed to extract all common refrigerants from cooling appliances and enables degassing of compressor oil from refrigerators containing CFC refrigerants.

Technical Data

| Power supply | 400 V, 3 Ph + N – 10 kW |

| Compressed air | 8 bar |

| Dimensions | 6,5 x 2,5 x 2,4 m |

| Weight | approx. 6.500 kg |

Order Number

| A-32820 | SEDA AFR Container |

| Alternative device | |

| A-32800 | SEDA AFR Stand alone unit |

| A-32810 | SEDA AFR Set |

Downloads

Benefits

- Mobile all-in-one solution

- Compact design

- Durable technology

- High safety standards with CE and ATEX certification

- Simple power connection

- The container cover doubles as a roof when opened

- Integrated spill trays

Video

Additional information

A roller conveyor system with a tilting mechanism facilitates the transport to and from the extraction point. Removed oil and gases are stored within the container, eliminating the need for external storage space. All relevant data is recorded and temporarily stored by the system.

The AFR container houses several specialized devices:

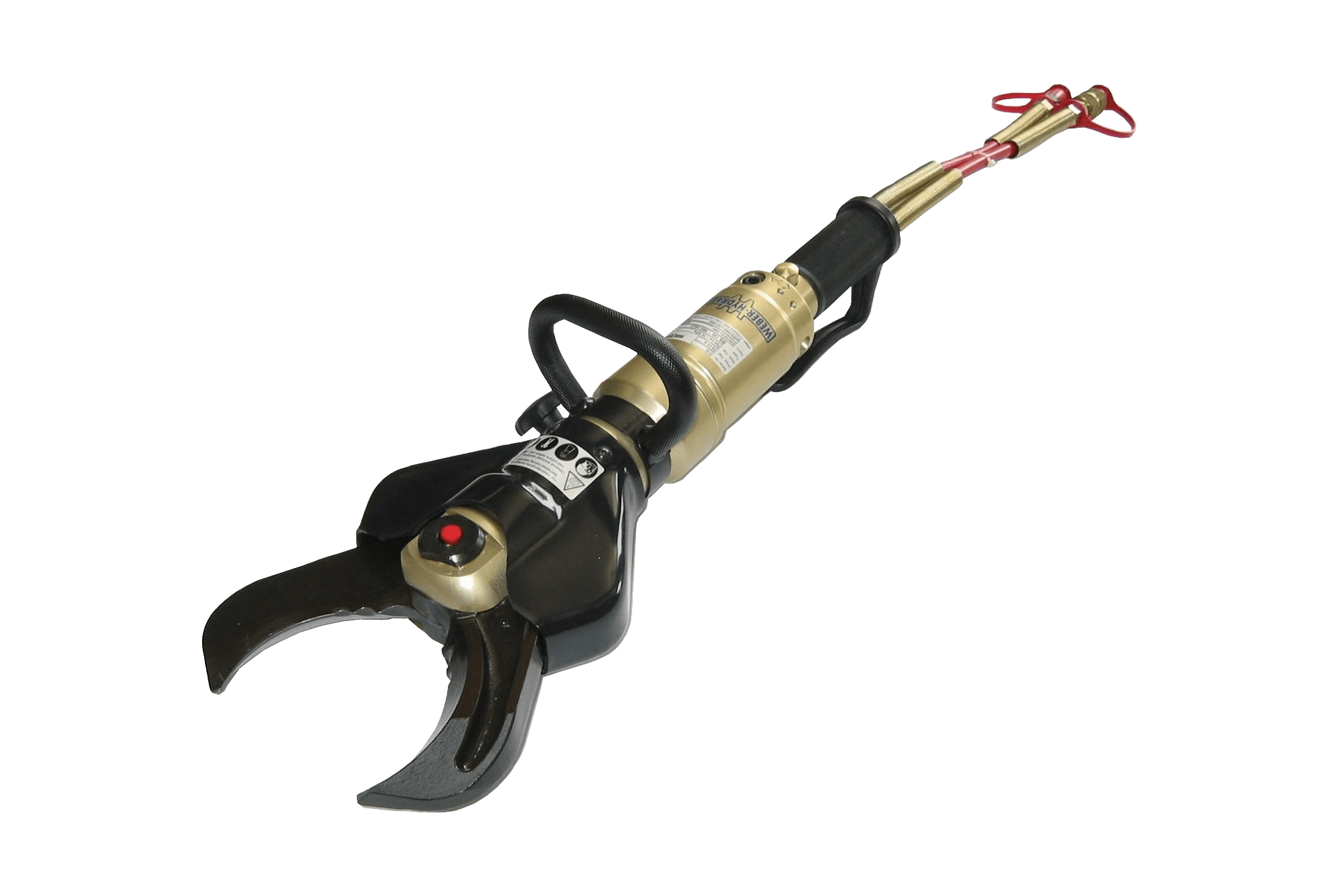

The AFR Ex is a machine designed for the processing of cooling appliances. The CFC Degassing Unit extracts gas and oil, separates them, degasses the oil, and compresses the gas for storage in reserve bottles. The Compressor is used for suction and compression of R600a gas and its filling into bottles along with providing compressed air for the tilting mechanism of the roller conveyor system. The roller conveyor system makes light work of the transport of appliances to and from the extraction point. Scales prevent overfilling of recovery bottles and ensure precise measurement of extracted quantities.